KHOSLA MACHINES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KHOSLA MACHINES P.LTD.

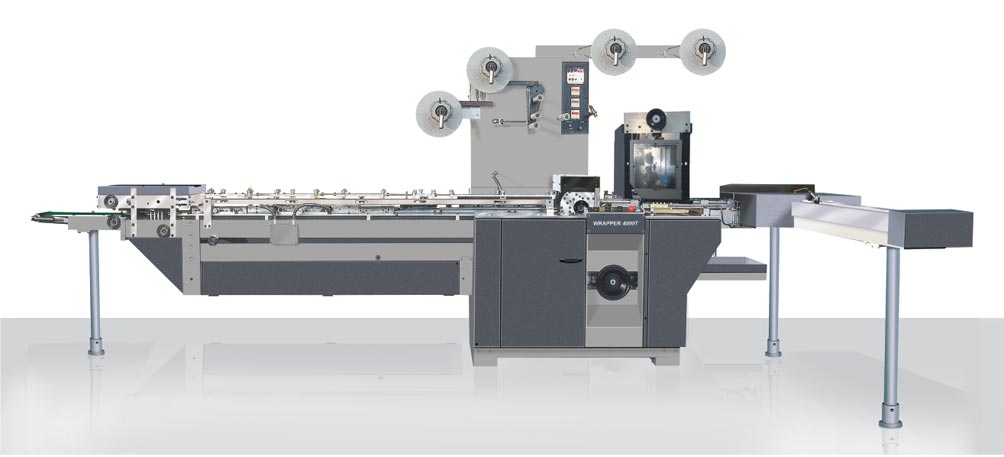

High Speed Toilet Soap Wrapping Machine

STANDARD FEATURES

» EASY AND QUICK CHANGE

All Wrapper 8000T’s timings for a particular size can be stored in the HMI as a recipe for that size. In future, whenever that size needs to be run, a simple click on its recipe restores timings of the machine suited to that size. Digital scale for future setting reference.

» HIGH PACKAGING QUALITY

Wrapper 8000T offers unique soap handling and wrapper control systems. Special emphasis is given to the soap feed system to give dent-free soap and on the discharge conveyor for positive control of wrapper skew.

» AUTOMATIC SPLICING

Machine has provision for mounting double rolls of wrapper and stiffener. As soon as the roll finishes it splices with the new rolls so that machine continues running. This saves the downtime for roll change and saves wrapper that gets wasted while threading the new roll.

»SPEED MATCHING TO SOAP STAMPERS

Wrapper 8000T offers 300+packs per minute output which makes it suitable for direct linkup with stampers. For high speed stampers, 2 Wrapper 8000T machines can be configured per line.

Highlights

» Fastest speed in its class

» Fully automatic link up to toilet soap stamper

» 7 Servo/PLC system with touch-screen controls by Allen Bradley

» Fully integrated safety Auto splicing of wrapper & stiffener rolls to save time

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.